In April of 2018, Georgia Institute of Technology’s Krone’s Engineered Biosystems Building (EBB) won the prestigious AIA COTE (Committee On The Environment) Top 10 Award. A Cooper Carry and Lake|Flato- designed project, EBB is one of the best examples of sustainable design in the country. Below is the story of that work including jury comments as originally published on the AIA COTE TOP 10 site.

INTEGRATION

Georgia Tech’s LEED Platinum Engineered Biosystems Building (EBB) is an innovative new model for research facilities. EBB challenges the silos of traditional laboratory design, creating a system of open lab neighborhoods that foster engagement. A departure from traditional lab structure, the “cross-cutting lab” implements continuous working lab space running down the spine of the building, with offices and meeting rooms in the wings. Daylight, outdoor views, a water harvesting system and other biophilic elements used throughout the program encourage interaction. Technology and intelligent design work together to create a multi-purpose open space with high levels of ecological performance.

“The Georgia Tech Engineered Biosystems Building weaves a large array of active and passive strategies into a highly tuned machine for this university research laboratory.” ~ Jury statement

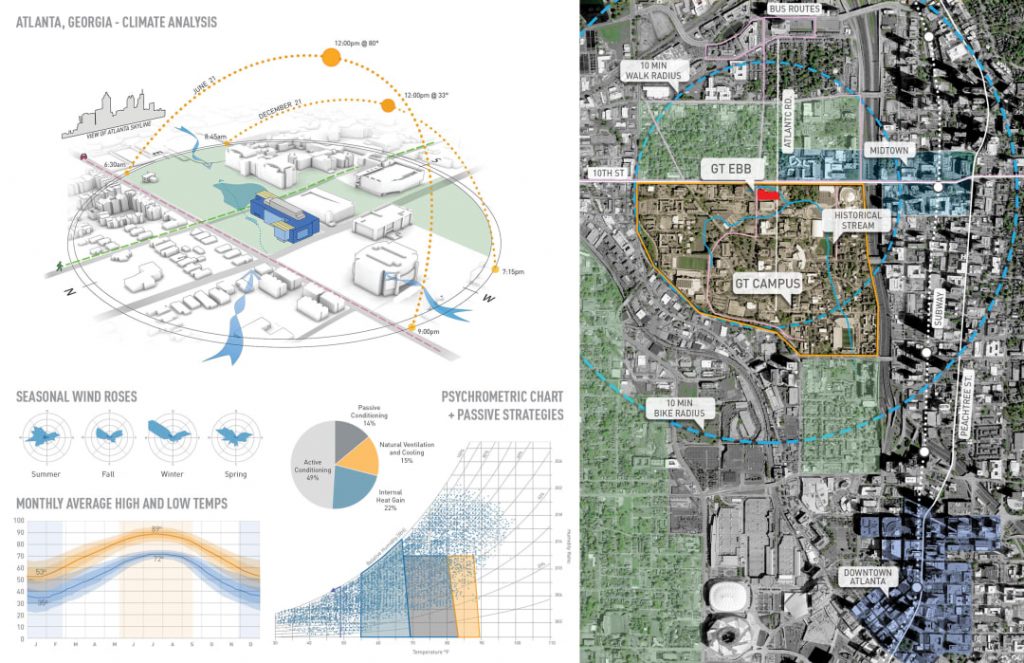

Georgia Tech’s Engineered Biosystems Building (EBB) provides nearly 200,000 sq ft to serve as a core bio-technological research building for Georgia Tech, as well as a model for further development of that section of the campus. The six-story design reevaluates laboratory design, merging the College of Sciences and College of Engineering to create an interdisciplinary environment that supports the acceleration of advanced research development. EBB was conceptualized as a research facility that would coerce interdisciplinary collaboration by reinforcing physical integration between researchers focused on chemical biology, cell biology, or systems biology. EBB challenges the silos of traditional laboratory design by creating a system of open lab neighborhoods that foster engagement. A departure from traditional lab structure, which typically prescribes adjoining rows of partitioned lab space throughout a building, the “cross-cutting lab” implements a program with continuous unobstructed working lab space running down the spine of the building with offices, meeting rooms and break and restrooms in the wings. Daylight, views to the outdoors, and other biophilic elements are used throughout the program to encourage interaction. The first building in what will become Georgia Tech’s Research Quad, EBB was envisioned to anchor the northern edge of campus. As an institution known for its advanced research, Georgia Tech required a high-performance facility and anticipated LEED certification at a high level. Integrative design process was used to bring together all project stakeholders at the beginning of design to set performance goals and metrics for the building. To achieve the passive design goals that were set for daylighting, energy, site ecology, and water, the project team created a vertically-scaled, narrow research building with a light footprint. EBB fits and functions within the Eco-Commons, a permanent and multi-purpose open space with high levels of ecological performance that lays over the entire campus master plan.

EBB’s narrow, vertical scale created a more porous, transparent edge to the campus, becoming a vibrant new entry into Georgia Tech. As an anchor to the northern edge of campus, EBB serves its nearby student residential neighborhood with green space and a new entry point to campus, and access to the nearby pedestrian and bike-access Promenade which extends to the center of campus. The vision of EBB is to co-locate and integrate faculty and students from several Colleges across campus, and the design team used connections to the landscape, daylight, and views to encourage collaboration. EBB’s open lab structure facilitates an interactive lab experience through ardent transparency and ease of collaboration. Break rooms and restrooms book-end open lab neighborhoods on alternating floors to encourage vertical circulation. Utilizing biophilic design in EBB has proven to be successful, as the demand from researchers to move into the building has been very high. On a recent post-occupancy evaluation visit, the design team interviewed a student that commented that she does not work in EBB but comes to the building frequently to do work. She loves the building – “the natural light, the feel of the lobby, and the views to the landscape.”

MANDATORY METRICS

Community engagement: A partnership was formed with stakeholders to share in the decision-making process including development of alternatives and identification of the preferred solution.

Walk score: 58

The Walk Score tool analyzes hundreds of walking routes to neighborhood amenities within ¼ mile (5-minute walk) earning up to 100 points.

Encouraged metrics

Estimated occupants who commute via alternative transportation (biking, walking, mass transit): 73 percent

ECOLOGY

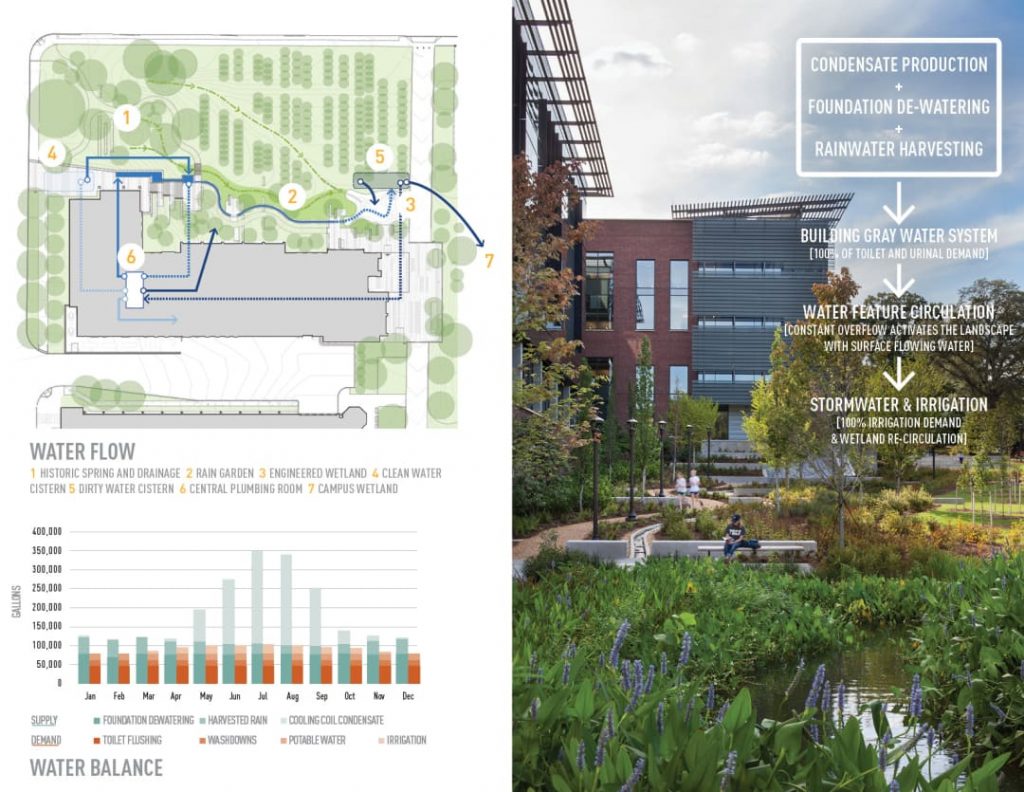

EBB aspires to enhance its site’s urban ecology performance to that of mature southern Piedmont woodlands while providing opportunities to promote academic community, through collaboration and interaction. EBB’s design was developed simultaneously with the campus Eco-Commons. The Eco-Commons was born from Georgia Tech’s Campus Master Plan, which sought a “50 percent reduction in stormwater runoff entering the Atlanta sewer system.” The Eco-Commons’ primary purpose is to manage stormwater runoff by receiving and storing stormwater. It directs runoff to a 10,000-gallon cistern, and additional stormwater runoff overflows into the cistern by way of a small wetland pond. The EBB site was previously an underutilized greyfield. It is the location of a drainage tributary that would have connected to the proposed Eco-Commons at the new glade. EBB’s narrow, vertical scale allowed a swale on the campus northern edge to be preserved and framed as an outdoor room, becoming part of the campus Eco-Commons stormwater management system. This open space is framed as an outdoor room for students to interact. As the first building in what will become Georgia Tech’s Research Quad, EBB has established ecology as the centerpiece for this new district on campus.

MANDATORY METRICS

Percentage of the site area designed to support vegetation: 61.9

Percentage of site area supporting vegetation before project began: 43.1

Percentage of landscaped areas covered by native or climate appropriate plants supporting native or migratory animals: 58.9

WATER

As a high-performance research facility, EBB supports the Georgia Tech campus by reflecting the historic site hydrology; creating attractive, usable outdoor spaces; visibly expressing and celebrating the concepts of low impact development; and successfully contributing to stormwater management. EBB is situated at the historic headwaters of the Atlanta water system, and it was anticipated that the historic stream would be intercepted in the building. Water from this stream is now collected in the basement of EBB then resurfaced in the fountain and collected in a series of cisterns for reuse and irrigation. A water balance calculation was performed at the beginning of the design process to evaluate opportunities to balance water demands with other available supplies for the project. The water balance revealed significant supply sources from air conditioning condensate and rainwater, and these were also captured in cisterns and reused for toilet flushing and outdoor features. The building produces more water than the building can use, and overflow from the cisterns create a rill that trickles through the site and terminates at a bioswale wetland. This ties into the campus’ hydrological story, showcasing site ecology and giving building occupants a place of respite.

“The focus on water in the building and the reuse of rainwater and air conditioning condensate in the landscape surrounding site is particularly impressive.” ~ Jury statement

MANDATORY METRICS

Predicted annual consumption of potable water for all uses, including process water: 520.5 gal/FTE or 79.43 percent reduction over LEED 2009 baseline

Is potable water used for irrigation? No

Encouraged metrics

Actual annual consumption of potable water for all uses: 520.5 gal/FTE or 79.43 percent reduction over LEED 2009 baseline (The process water data entered in this form is from measured data, not a design estimate. The actual water use for this project has been higher than design estimates. We discovered through post-occupancy evaluation that much of this is due to a sinkhole on the west side of the site that caused an increase in potable water use for the fountain. The sinkhole has been repaired and we have observed a decrease in potable water use since then.)

Percentage of water consumed onsite comes from rainwater capture: 11

Percentage of water consumed onsite comes from greywater/blackwater capture and treatment: 10

Percent of rainwater that can be managed on site: 23

Metrics of water quality for any stormwater leaving the site: 80 percent of TSS removed from stormwater runoff

Learn more via the EPA’s Guidance Specifying Management Measures for Sources of Non-Point Pollution in Coastal Waters (Chapter 4, table 4-7).

ECONOMY

“The Georgia Tech Engineered Biosystems Building weaves a large array of active and passive strategies into a highly tuned machine for this university research laboratory.” ~ Jury statement

Georgia Tech’s original expectation was for EBB to take up the entire site. At the onset of design, the team reviewed the site to maximize the FAR. Through several conceptual planning designs, the team could decrease gross square footage through use of open offices, and right-size the building footprint to occupy only half of the site. The remaining site is preserved as green space adjacent to the residential neighborhood to enjoy. EBB is located on the south half of the site, proximate to an existing parking garage, so the building could utilize the existing parking capacity instead of creating new parking. The project uses cast-in-place concrete as the primary construction material for its sustainability, durability, floor-to-floor height, and economy, at $28 per square foot for the frame. Concrete additionally has superior vibration resistance and dampening characteristics, which made it an ideal choice for a building containing laboratories and high-traffic areas. The concept of using less is more is unique in lab buildings, and EBB conserves resources by design through dematerialization. The team set a goal during an early design charrette to get multiple uses and benefits through every material by systems integration and using exposed systems and structure as finish.

MANDATORY METRICS

Cost per square foot: $414.96

Encouraged metrics

Comparable cost per square foot for other, similar buildings in the region: $491.73 (from general contractor)

Estimated annual operating cost reduction (identify baseline): 33.36 percent over ASHRAE 90.1-2007

ENERGY

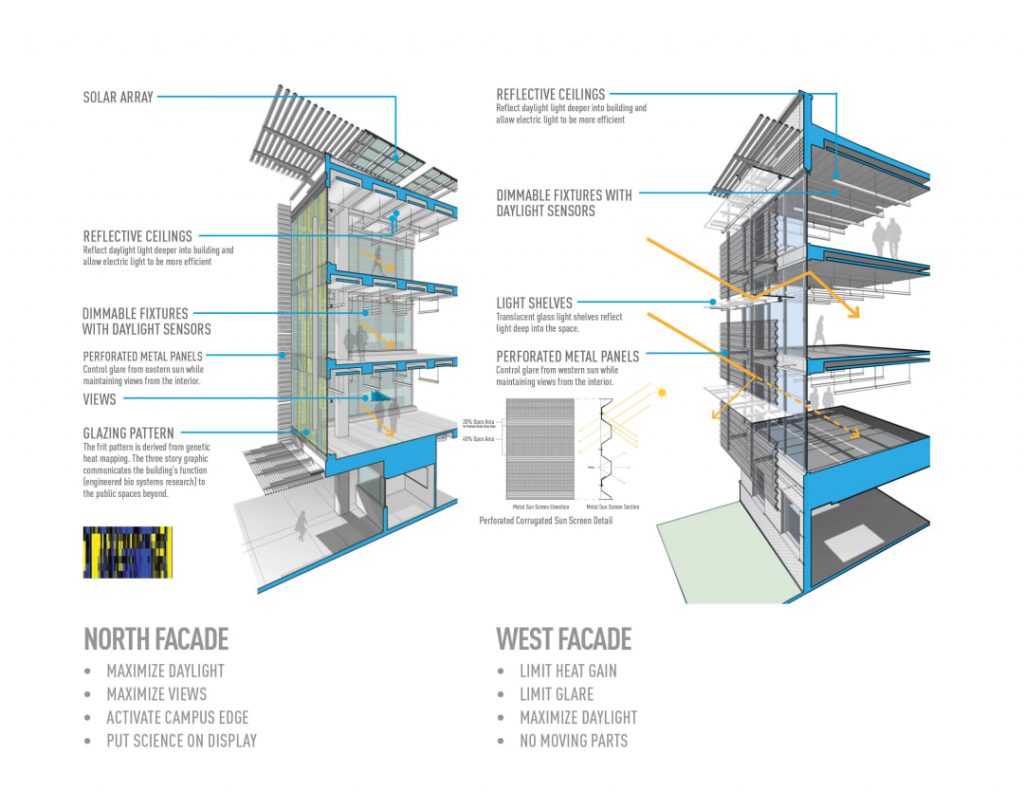

EBB’s goal was to achieve an energy use intensity (EUI) in the 1st quartile of energy performance to match or surpass similar existing buildings at Georgia Tech. Comparable buildings averaged an EUI of 490 kBtu/sq ft/yr. The project team designed EBB to exceed this goal with an estimated EUI of 136.1 kBtu/sq ft/yr. The design team’s approach to energy reduction started with judicious fenestration design. West-facing windows in support labs were minimized to tiny slits in the brick façade. Perforated metal panels on the west and east facades were used to limit heat gain during summer months but allow for daylight and views. Chilled beams reduce the amount of fan energy needed to push conditioned air through the building. Vacancy sensor control of lighting, heat recovery from relief/exhaust air, high efficiency condensing boilers, unoccupied setback of ventilation rates in lab and lab support (from 6 ACH to 4 ACH), demand controlled ventilation in non-lab spaces, and reduced (25 percent below ASHRAE allowable) lighting power density were all included to reduce energy use. EBB also includes two on-site renewable energy generating systems, solar PV panels for electrical production and flat panel solar water heating systems supplementing the domestic hot water generators.

“Laboratory buildings are typically heavy water and energy users, yet the design team managed to show that vast improvements can be achieved through ingenuity and integrated design.” ~ Jury statement

Mandatory metrics

Predicted consumed energy use intensity (EUI): 136.1 kBtu/sq ft/yr

Energy use intensity (EUI) refers to total energy use by the facility including energy purchased from utilities and provided by on-site renewable sources.

Predicted Net EUI: 134.3 kBtu/sq ft/yr

Predicted Net carbon emissions: 7,495,447.2 lb/sq ft/yr

Net carbon emissions refers to net purchased energy use (total energy use, less any energy generated on-site from renewable resources).

Predicted reduction from national average EUI for building type: 69 percent

Predicted lighting power density: 0.66 W/sq ft

Encouraged metrics:

Actual Consumed Energy Use Intensity (Site EUI): 182.06 kBtu/sq ft/yr

Actual net EUI: 180.67 kBtu/sq ft/yr

Actual net carbon emissions: 9,427,148 lb/sq ft/yr

Actual reduction from national average EUI for building type: 49

WELLNESS

The team created a vertically-scaled, narrow building to maximize daylighting penetration and preserve views to northern Midtown across Atlanta. The building program was organized to provide maximum daylight to the graduate student office area and the large open research labs, with the smaller support labs flanking the southern edge of the building with smaller windows. The north-facing graduate student offices were heightened to fit into the structural pans to maximize the north daylight into the building. Labs are highly visible from the main circulation, putting the research on display and borrowing daylight and views from the large open offices that are adjacent. The building exterior is reflective of interior building program where large north facing bay windows enhance daylight penetration through open office space to the labs. Open office spaces have uniform northern light and views of the wetland landscape. Daylight is important, but control of glare is also critical for the enjoyment of the work space. Sun studies informed the sunscreen designs for the south, east, and west elevations. The west elevation also includes automatic internal shades and light shelves. Vertical circulation paths were made prominent to encourage use of stairs and promote healthier circulation for inhabitants.

“Thoughtful organization allows for an abundance of daylight to reach the laboratory spaces as well as the offices.” ~ Jury statement

Mandatory metrics

Percentage of floor area or percentage of occupant work stations with direct views of the outdoors: 90.2

Percentage of floor area or percentage of occupant work stations within 30 feet of operable windows: 0.

Percentage of floor area or percentage of occupant work stations achieving adequate light levels without the use of artificial lighting: 15 percent >300 lux at 3pm March 21

Is this project a workplace? Yes.

How many occupants per thermal zone or thermostat: 5

Occupants who can control their own light levels: 97.2 percent

Encouraged metrics

Peak measured CO₂ levels during full occupancy: 588ppm

Annual daylighting performance: 35 of regularly occupied area achieving at least 300 lux at least 50 percent of the annual occupied hours.

RESOURCES

Materials were chosen to reinforce the campus identity and sense of place. Composed of diverse wood types from the site, EBB’s interiors are outfitted in a hybrid of wood panels of varying colors and textures, authentically connecting interiors with the surrounding environment. All usable 80-year old oaks removed from the site for the building footprint were salvaged and 100 percent of those salvaged oaks were used in material finishes and construction. The treads of all the monumental stairs utilize lumber that was milled from these trees. EBB reinforces the architectural language of surrounding buildings by using brick, wood, and other materials local to the region. 55 percent of project materials by cost were sourced within 500 miles. 36 percent of project materials were Georgia-based. HVAC and structural systems were coordinated to become part of the building aesthetic, minimizing the need for finish materials. The slab was right-sized to use less cement, further reducing material volume (and cost). Optimizing the amount of material used not only decreased EBB’s carbon intensity, but improved the indoor environment for inhabitants. Commonly used lab finishes often include chemicals of concern and high VOC content, so the design team eliminated these products where possible, and used low-emitting materials throughout.

Mandatory metrics

CO₂ intensity: 82.9 metric tons

Estimated carbon emissions associated with building construction:

CO₂ intensity refers to the estimated carbon emissions associated with building construction, including the extraction and manufacturing of materials used in construction. Learn more about The Construction Carbon Calculator Tool.

Encouraged metrics

Percentage (by weight) of construction waste diverted from landfill: 99.7

CHANGE

EBB is the first building in what will become Georgia Tech’s Research Quad, so the team was cognizant of how the building would facilitate district development. EBB took on the duty of a central receiving facility for this new three building campus zone. EBB contains instrument cores and a large subgrade facility designed with flexibility as well as shelled growth space and circulation links to future buildings. Careful consideration was given to not only initial materials and pedestrian flows, but for connection and service to future buildings as well. The interdisciplinary program necessitates the building design to be flexible and adaptable for the wide range of anticipated uses. The project team also addressed the “bandwidth” of critical systems to adapt over time. The building is fitted with runs of empty conduit to facilitate easy installation of additional cables. The design also has sufficient air flow to accommodate additional fume hoods in laboratory areas. Georgia Tech’s commitment to energy future and resilience is architecturally expressed through a large solar rooftop trellis. Since occupancy, the solar photovoltaic and solar hot water systems have generated 1 percent of the total building electrical load and 23 percent of the total estimated domestic water heating gas consumption.

Mandatory metrics

Percentage of project floor area, if any, that represents adapting existing buildings: 0

Anticipated number of days the project can maintain function without utility power: 1

Encouraged metrics

Percentage of power needs supportable by onsite power generation: 1.43

DISCOVERY

The design team has worked closely with the owner post-occupancy to assess EBB’s performance relative to its aggressive sustainability and research goals. “The EBB will support Georgia Tech’s strategic goals to strengthen our Institute’s biology and health sciences activities. As fossil fuels continue to be depleted and cause harm to the environment, it is important that Georgia Tech play an important role in reducing our carbon footprint while advancing alternative technologies, many of which are being developed by our own faculty,” stated Howard S. Wertheimer, FAIA, LEED AP, Director of Capital Planning and Space Management for Georgia Tech. The process of accurately monitoring and optimizing operations is ongoing, and has identified many opportunities for improvement. EBB is also a part of Georgia Tech’s Smart Energy Campus Program, a sustainability research initiative that collects data from energy utility systems throughout campus to inform energy planning and consumption at Georgia Tech. EBB is playing a major role in the program’s exploration in retrocommissioning research buildings using ACH reduction and exhaust strategies. A comprehensive wind study was recently conducted on campus to understand how EBB and other lab buildings can reduce energy associated with ventilation by leveraging climate conditions.

Mandatory metrics

Post-occupancy evaluation summary: The design team is performing extensive commissioning and post-occupancy evaluation on EBB, and has identified and addressed several performance issues through this rigorous process. For example, EBB uses fume hoods with an “auto-close” function to manage energy consumption. The design team identified many hoods in the project with auto-close function issues or where users had disabled the feature. It was also discovered during a post-occupancy visit that the weather station installed at EBB was not operating. An issue with the fountain make-up water valve was discovered and corrected. The design team monitors energy and water use remotely, and makes post-occupancy visits to measure air quality and daylight levels. Results and resolution to issues are discussed regularly with Georgia Tech. User experience has also been studied through occupant surveys and post-occupancy visits. On one such visit, the design team recorded occupancy counts for different spaces throughout the day to assess the project’s social and campus community effectiveness. The strategically located food hub near the public entry and seminar rooms proved to be a popular location for informal collaboration and campus meetings, and is even the regular gathering spot for a mothers group not associated with Georgia Tech.

Project Information:

Project attributes

Year of design completion: 2013

Year of substantial project completion: 2014

Gross conditioned floor area: 207,790 sq ft

Gross unconditioned floor area: 4,676 sq ft

Number of stories: 6

Project Climate Zone: ASHRAE 3A

Annual hours of operation: 2,920

Site area: 142,052 sq ft

Project site context/setting: urban

Cost of construction, excluding furnishing: $91,613,210

Number of residents, occupants, visitors: 582

Project Team

Architect of Record: Cooper Carry

Daylighting: Integrated Design Lab

Ecological Services: Biohabitats

Energy Performance: TLC Engineering for Architecture

Engineer – Civil: Long Associates

Engineer – MEP: Newcomb & Boyd

Engineer – Structural: Uzun + Case

General Contractor: McCarthy Building Co.

Lab Planning Consultant: RFD

Landscape Architect: jB+a

Landscape Architect: Nelson Byrd Woltz

Third party rating systems

LEED: Platinum